Page 42 - EXPORT MAGAZINE

P. 42

C OMP ANY

INDUPLAST PACKAGING GROUP

WE SHAKE YOUR BEAUTY

MAKING THE MOST OUT

OF PACKAGING

Sustainability and innovation:

The Future of packaging with Refillable Jars

In recent years, sustainability has become one of the most discussed and sought-after topics by

consumers worldwide. Growing awareness of the environmental impact of the products we use daily

has led to a true revolution in the packaging world, where a new trend is emerging: refillable jars.

These packaging systems, which allow the container to be reused and only the inner product to be

replaced, fully align with the 3 R philosophy: Reduce, Reuse, Recycle.

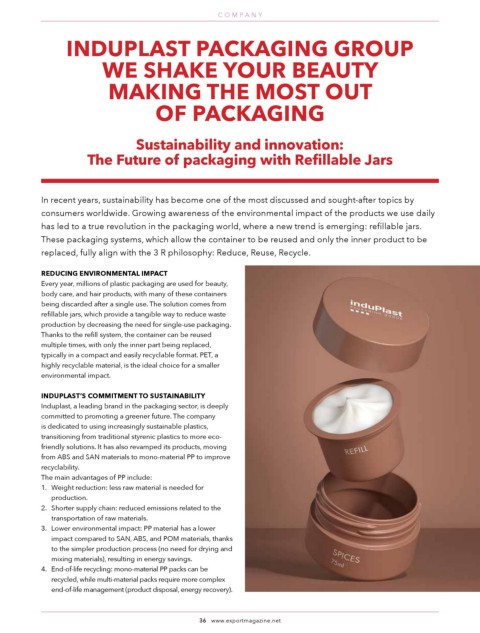

REDUCING ENVIRONMENTAL IMPACT

Every year, millions of plastic packaging are used for beauty,

body care, and hair products, with many of these containers

being discarded after a single use. The solution comes from

refillable jars, which provide a tangible way to reduce waste

production by decreasing the need for single-use packaging.

Thanks to the refill system, the container can be reused

multiple times, with only the inner part being replaced,

typically in a compact and easily recyclable format. PET, a

highly recyclable material, is the ideal choice for a smaller

environmental impact.

INDUPLAST’S COMMITMENT TO SUSTAINABILITY

Induplast, a leading brand in the packaging sector, is deeply

committed to promoting a greener future. The company

is dedicated to using increasingly sustainable plastics,

transitioning from traditional styrenic plastics to more eco-

friendly solutions. It has also revamped its products, moving

from ABS and SAN materials to mono-material PP to improve

recyclability.

The main advantages of PP include:

1. Weight reduction: less raw material is needed for

production.

2. Shorter supply chain: reduced emissions related to the

transportation of raw materials.

3. Lower environmental impact: PP material has a lower

impact compared to SAN, ABS, and POM materials, thanks

to the simpler production process (no need for drying and

mixing materials), resulting in energy savings.

4. End-of-life recycling: mono-material PP packs can be

recycled, while multi-material packs require more complex

end-of-life management (product disposal, energy recovery).

36 www.exportmagazine.net